Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Опубликовано в Знание - Производитель листов ПЭТ/ПП/ПС с 20-летним опытом

PET (Polyethylene terephthalate) plastic roll refers to a type of plastic material that is commonly used for packaging purposes. PET is a thermoplastic polymer resin of the polyester family and is widely used for making containers for beverages, food, and other consumer products.

A PET plastic roll would typically be a roll of thin PET plastic sheeting or film, which can be used in various applications such as packaging, labeling, or even as a substrate for printing. PET plastic is known for its clarity, strength, and recyclability, making it a popular choice in the packaging industry. It's often used in the production of bottles, jars, trays, and other packaging materials. Additionally, PET plastic is highly versatile and can be easily shaped and molded into different forms to suit specific packaging needs.

PET plastic rolls provide an efficient and cost-effective solution for packaging needs across a wide range of industries, including food and beverage, cosmetics, pharmaceuticals, and more.

1. Transparency: PET plastic roll is clear, allowing for visibility of packaged products.

2. Strength: PET plastic roll is strong and resistant to tearing, making it suitable for packaging items of various shapes and sizes.

3. Lightweight: PET plastic roll is lightweight, which helps reduce transportation costs and environmental impact.

4. Recyclability: PET plastic roll is recyclable, contributing to sustainability efforts in the packaging industry.

5. Versatility: PET plastic rolls can be easily customized and tailored to specific packaging requirements, including printing, shaping, and sealing.

Polyethylene terephthalate (PET) plastic rolls have a specific set of physical properties that are critical to their performance in a variety of applications. The following are some of the main physical properties of PET plastic rolls:

1. Density: The density of PET plastic roll is about 1.3 grams/cubic centimeter, which makes it relatively light but also has a certain sense of weight, which contributes to the stability of product packaging.

2. Tensile Strength: PET plastic roll has excellent tensile strength, typically between 6,000 and 10,000 pounds per square inch, making it a strong material suitable for use in a variety of packaging and industrial applications.

3. Compressive Strength: PET plastic roll has good resistance to pressure, so it is not prone to deformation or cracking even under high pressure.

4. Hardness: PET plastic roll has moderate hardness and sufficient rigidity and toughness to prevent it from being easily deformed or deformed during packaging and processing.

5. Glass Transition Temperature (Tg): The glass transition temperature of PET plastic is about 70 to 80 degrees Celsius, which is the critical temperature at which it softens at high temperatures. Below this temperature, PET plastic roll generally remains rigid and shape-stable.

6. Coefficient of thermal expansion: PET plastic roll has a relatively low coefficient of thermal expansion, which means it is not prone to significant dimensional changes when temperature changes, which is critical for packaging applications in high or low temperature environments.

7. Transparency: PET plastic roll has good transparency and optical properties, allowing it to effectively display products in packaging and increase product appeal.

8. Electrical Insulating Properties: PET plastic roll has excellent electrical insulating properties, making it ideal for use as an insulating material in electronic and electrical equipment.

9. Moisture absorption: PET plastic roll has a relatively low moisture absorption rate, which helps maintain its physical properties and dimensional stability in humid environments.

10. Weather resistance: PET plastic roll has good weather resistance and can resist ultraviolet radiation and oxidation, making it suitable for outdoor applications and product packaging that are exposed to sunlight for a long time.

| Water absorption | 0.06%~0.129% |

| Impact strength | 64.1~128J/m |

| Rockwell hardness | M 90~95 |

| Elongation | 1.8%~2.7% |

| Melting point | 250~255°C |

| Operating temperature | -100~120°C |

| Flexural strength | 148~310MPa |

PET plastic rolls have good chemical stability and durability, making them one of the ideal materials widely used in packaging, industry and manufacturing fields.

1. Chemically inert: PET plastic roll has good chemical stability and is inert to most common chemicals. This makes it ideal for packaging sensitive products such as chemicals, pharmaceuticals and food.

2. Solvent resistance: PET plastic roll has good resistance to many solvents, including alcohols, ketones, ethers and many organic solvents. However, under certain extreme conditions, such as high temperatures, high concentrations of solvents, or prolonged contact, PET plastic may be corroded by solvents.

3. Heat resistance: PET plastic roll has good heat resistance and can usually withstand temperatures up to 70 to 80 degrees Celsius without deformation or softening. However, prolonged exposure to high temperatures can cause changes in the molecular structure of the plastic.

4. Acid and alkali stability: PET plastic roll has good stability under general acid and alkaline conditions, but may be corroded under strong acid or alkali conditions.

5. Hydrolyzability: PET plastic roll is not easily hydrolyzed under normal conditions, but hydrolysis reactions may occur under high temperature, high humidity and strong acid and alkali conditions.

6. Light stability: PET plastic roll has good light stability and can resist ultraviolet radiation and photo-oxidation, thus extending its service life.

7. Plasticity: PET plastic roll has good plasticity and can be made into products of various shapes through heating and processing, such as extrusion, blow molding, injection molding, etc.

8. Flammability: PET plastic roll has certain flammability, but its combustion performance is affected by additives and fillers. Normally, PET plastic produces black smoke and harmful gases when burned, so fire safety needs to be paid attention to when designing and using it.

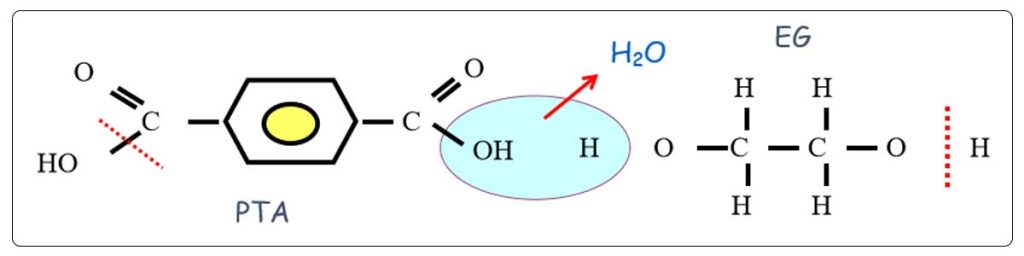

PET plastic roll is a newly developed new type of plastic product, so what is the difference between it and our traditional plastic? First of all, the production process of this material is more complicated. It is produced through a series of compression polymerization processes using high-precision machinery.

The plastic we generally see is a translucent substance, but the transparency of this material It can be changed according to its specific requirements, and because of its good ductility and plasticity, it can also be placed in our home or office as a decoration. At the same time, even if its life is reached, it will burn when it needs to be recycled. It will not produce any polluting gas, and the harm to the environment is minimal. Pulixin rigid PET plastic rolls are mainly used for Fresh Meat packaging, Processed Meat Packaging, Poultry packaging, Fish packaging, Cheese packaging, Pasta Packaging, Medical Packaging, MAP and Vacuum Packaging, Electronic product trays, Folding boxes, etc.

| Product name | PET Plastic Roll, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Форма | Рулон/лист |

| Толщина | 0.18~2.0mm |

| Ширина | 300~1400мм |

| Качество | Virgin/Recycled |

| ДОМАШНИЙ ПИТОМЕЦ Диаметр рулона | ≤38 дюймов |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Упаковка | Полиэтиленовая пленка внутри + крафт снаружи + поддон (диаметр бумажной трубки: 76 мм, толщина: 10 мм) |

| Цвет | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Производительность | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Технология обработки | Thermoforming Vacuum Blister Forming, Die Cutting. |

| твердость | Rigid/Semi-rigid |