Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Опубликовано в Новости - Производитель листов ПЭТ/ПП/ПС с 20-летним опытом

On May 23, 2024, the PET plastic sheet rolls produced by our company were successfully shipped to the Philippines. This batch of PET plastic sheets will be used for packaging in local food, medicine, electronics, toys and other industries, providing high-quality packaging solutions to Philippine customers.

The Philippines is one of the most popular countries in Southeast Asia, with a population of over 110 million. With the rapid economic development and significant improvement in living standards, the food packaging industry in the Philippines is also growing rapidly. Among various packaging materials, PET plastic sheets have gradually become the mainstream material in the food packaging industry due to its excellent performance and environmental protection advantages. PET plastic not only has good transparency and strength, but also has high heat resistance and impact resistance, making it outstanding in protecting food safety and extending shelf life. In addition, PET materials are recyclable and comply with the principles of sustainable development, further promoting its wide application in the food packaging industry.

1. Excellent transparency

PET plastic sheet rolls are highly transparent, making the food inside the package clearly visible, helping consumers intuitively judge the quality of the food.

2. High strength and durability

PET plastic sheet rolls has high strength and impact resistance, which can effectively protect the food in the package from external physical damage.

3. Good heat resistance

PET plastic sheet rolls can remain stable at higher temperatures and are suitable for food packaging that requires heating or heat sealing.

4. Lightweight

Compared with other packaging materials, PET plastic sheet rolls are lightweight, helping to reduce transportation costs and carbon emissions.

5. Excellent barrier properties

PET plastic sheet rolls have good gas and moisture barrier properties, which can effectively extend the shelf life of food.

6. Environmental protection

PET material can be recycled, meets the requirements of environmental protection and sustainable development, and reduces the impact on the environment.

7. Excellent processing performance

PET plastic sheet rolls are easy to process and can be made into various shapes of packaging through various molding processes (such as thermoforming and vacuum forming).

8. Chemical stability

PET plastic sheet rolls has good tolerance to most chemicals and is not prone to chemical reactions with food, ensuring food safety.

9. Cost-effective

While the initial investment may be higher, PET plastic sheet roll is more cost-effective in the long run due to its durability and recyclability.

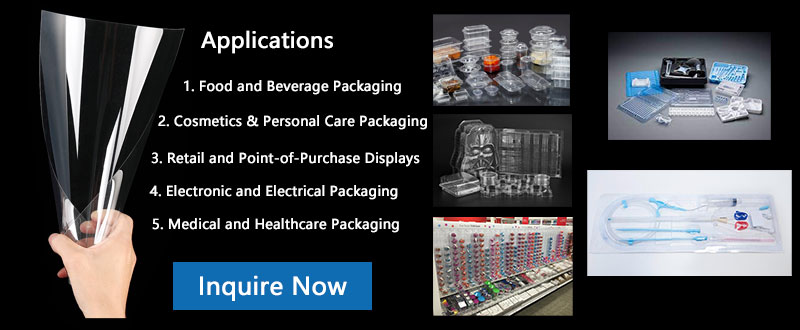

Pulixin Packaging Materials (HongKong) Co., Ltd. is Manufacturer & Exporter of PET plastic sheet rolls, professionally supplies all kinds of Rigid PET palstic sheet rolls, PET Plastic usually divided into APET, PETG, GAG and RPET and mainly used for thermoforming, vacuum forming & blister packaging.

We have passed a variety of international certifications and obtained relevant certificates like ISO, RoHS, SGS,FDA and GRS. Our PET Plastic exported to 40+ countries Distribute in America, Europe, Africa, Southeast Asia etc.

Pulixin (HongKong) has the following advantages in producing PET plastic sheet rolls:

1. Advanced production equipment and technology: Pulixin (HongKong) has modern production facilities and advanced production technology, which can ensure the production of high-quality PET plastic sheet rolls. These devices and technologies enable precise control of product thickness, transparency and strength.

2. High-quality raw materials: Pulixin (HongKong) uses high-quality PET raw materials to ensure that the sheets produced have excellent properties, including high transparency, strength and heat resistance.

3. Strict quality control: Pulixin (HongKong) implements strict quality control measures. Every link from raw material procurement to production process is closely monitored to ensure that the final product meets international quality standards.

4. Environmental protection and sustainable development: Pulixin (HongKong) is committed to environmental protection and sustainable development, using recyclable PET materials, and minimizing waste and energy consumption during the production process to reduce the impact on the environment.

5. Customized production capabilities: Pulixin (HongKong) can provide customized PET plastic sheet rolls production services according to customer needs, including different thicknesses, widths and colors, to meet various special application requirements.

6. Fast delivery and quality service: Pulixin (HongKong) has an efficient production and logistics system that can quickly respond to customer orders and ensure timely delivery. In addition, the company also provides high-quality customer service to answer questions encountered by customers during use.

7. Technology R&D and innovation capabilities: Pulixin (HongKong) focuses on technology R&D and product innovation, continuously improves production processes and product performance, and launches new PET sheet products that are more in line with market demand.

8. Wide market recognition: Pulixin (HongKong)'s PET plastic sheet rolls enjoy a good reputation in domestic and foreign markets and have been recognized and trusted by many customers.

HIPS plastic sheet roll is a versatile and cost-effective packaging material that has several applications in the food packaging, medical, consumer goods, and manufacturing industries. Its toughness, and lightweight make it ideal for packaging products that require visual appeal and protection during transportation and handling.

PP plastic sheet roll is a versatile and cost-effective packaging material that has several applications in the food packaging, medical, consumer goods, and manufacturing industries. Its toughness, and lightweight make it ideal for packaging products that require visual appeal and protection during transportation and handling.