Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Мы свяжемся с вами в течение 24 часов по поводу отправки бесплатных образцов

Опубликовано в Знание - Производитель листов ПЭТ/ПП/ПС с 20-летним опытом

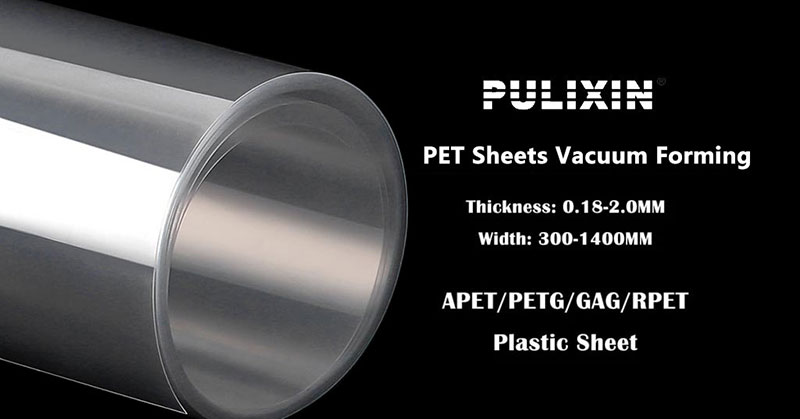

PET (Polyethylene Terephthalate) sheets are widely known for their versatility and excellent properties, making them a popular choice for packaging applications. One of the key manufacturing processes that utilizes PET sheets is vacuum forming. In this article, we will explore the concept of PET sheets vacuum forming, its benefits, and its impact on packaging solutions.

Vacuum forming is a process that involves heating a PET sheet and shaping it using vacuum pressure. The PET sheet is placed over a mold, and heat is applied to soften the material. Once the sheet reaches the desired temperature, a vacuum is applied, pulling the sheet tightly over the mold's contours. As the sheet cools, it solidifies and adopts the shape of the mold.

Vacuum forming PET sheets offers several benefits that enhance packaging solutions:

PET sheets vacuum forming allows for the creation of customized shapes and sizes to meet specific packaging requirements. The flexibility of PET sheets combined with the vacuum forming process enables the production of packaging solutions with intricate designs and unique contours. This flexibility opens up opportunities for creative and visually appealing packaging designs.

PET sheets are lightweight by nature, and vacuum forming does not add significant weight to the packaging. This lightweight characteristic helps reduce overall packaging weight, resulting in cost savings in transportation and shipping. Additionally, the efficient use of PET material in the vacuum forming process contributes to cost-effectiveness.

Vacuum-formed PET sheets provide excellent impact resistance and protection for packaged products. The formed sheets create a sturdy and protective enclosure that safeguards the contents from external forces, such as shocks and vibrations during handling and transportation. This ensures that the packaged items remain safe and intact throughout the supply chain.

PET sheets offer exceptional transparency, and vacuum forming retains this transparency in the final packaging. The clear visibility of the product enhances its market appeal, allowing consumers to see and evaluate the quality, color, and condition of the contents. This visibility can significantly influence purchasing decisions and create a positive brand image.

Vacuum-formed PET sheets find extensive applications in various industries, including:

PET sheets vacuum forming is commonly used in the food and beverage industry for packaging items such as trays, containers, and blister packs. The ability to create custom shapes and sizes allows for efficient space utilization and the presentation of food products in an appealing manner. The transparency of PET sheets enhances the visibility of the packaged food, enticing consumers with a clear view of the contents.

Vacuum-formed PET sheets are utilized in the packaging of electronics, consumer goods, and household products. The custom-formed trays or blisters provide secure compartments for items such as mobile phones, small appliances, toys, and cosmetics. The protective nature of vacuum-formed PET sheets ensures that the products are safeguarded during shipping and storage.

In the medical and pharmaceutical industries, vacuum-formed PET sheets are widely used for packaging items like medical devices, surgical tools, and pharmaceutical products. The precise shaping capabilities of vacuum forming enable the creation of trays and blisters that securely hold and protect delicate medical equipment and medication. The hygienic and sterile properties of PET sheets make them suitable for medical applications.

Vacuum-formed PET sheets play a significant role in the creation of attractive retail displays and point-of-sale packaging. The ability to form PET sheets into unique shapes and contours allows for the development of eye-catching displays that highlight the product and brand. Vacuum-formed PET sheets can be used to create display stands, product holders, and signage, enhancing the visual appeal and promotional efforts in retail environments.

PET sheets vacuum forming is a valuable manufacturing process that enhances packaging solutions in various industries. The ability to create custom shapes, lightweight yet durable packaging, and enhanced product visibility are key advantages of vacuum-formed PET sheets. Industries such as food and beverage, electronics, medical, and retail benefit from the versatility and protective properties of vacuum-formed PET sheets.

When considering packaging solutions, exploring the potential of PET sheets vacuum forming can provide numerous benefits, including cost-effectiveness, design flexibility, and product protection. The customization options, impact resistance, and transparency offered by vacuum-formed PET sheets contribute to visually appealing and functional packaging designs.

By leveraging the advantages of PET sheets vacuum forming, businesses can create packaging solutions that not only protect and preserve their products but also captivate consumers and contribute to a positive brand image.