We will contact you within 24 hours about sending free samples

We will contact you within 24 hours about sending free samples

Blister packaging is a type of packaging where a product is placed within a pre-formed plastic blister (or cavity) and then sealed with a backing material, often made of paperboard or another type of plastic. This type of packaging is commonly used for small consumer goods, pharmaceuticals, electronics, and other products.

Blister packaging products mainly include: Blister packaging blister, Blister packaging tray, Blister packaging box, etc.

The types of blister packaging can be divided into: card blister packaging, blister card blister packaging, double blister blister packaging, half blister blister packaging, half-fold blister blister packaging, three-fold blister blister packaging, etc.

Blister packaging can be divided into electronic blister packaging, IT blister packaging, industrial parts blister packaging, toy blister packaging, stationery blister packaging, food blister packaging, handicraft blister packaging and cosmetic blister packaging, etc.

HIPS stands for High Impact Polystyrene, a type of plastic commonly used in packaging due to its toughness, rigidity, and clarity. HIPS plastic rolls for blister packaging are thin sheets of high impact polystyrene that are rolled up for easy handling and storage.

Blister packaging involves forming a plastic cavity (blister) over a mold and then sealing it with a backing material, often made of paperboard or foil. HIPS plastic rolls are used to create the blister portion of this packaging. The plastic is heated and formed over a mold to create the desired shape, and then the product is placed inside the cavity before sealing.

Blister packaging is commonly used for consumer products such as pharmaceuticals, electronics, toys, and small consumer goods because it offers protection, visibility of the product, and tamper resistance. HIPS plastic rolls are favored for blister packaging because they offer good impact resistance, clarity, and ease of processing during manufacturing.

1. HIPS plastic blister packaging produces low static electricity, which is suitable for the packaging of products requiring low static electricity.

2. HIPS blister packaging is easy to vacuum form, and the product has good anti-attack performance.

3. HIPS blister packaging has good hygienic properties and can be directly contacted with food without producing harmful substances.

4. HIPS blister packaging is easy to be colored, and can be made into PS blister packaging products of different colors, and produced into HIPS blister packaging vacuum covers of different colors.

5. The hardness of HIPS blister packaging is good, and the hardness of HIPS blister packaging material is better than that of other sheet materials of the same thickness. Thermoformed cups can be used as hot and cold drink cups.

6. HIPS blister packaging meets the requirements of environmental protection and can be recycled and reused. When HIPS blister packaging waste is incinerated, it does not produce harmful substances that can harm the environment.

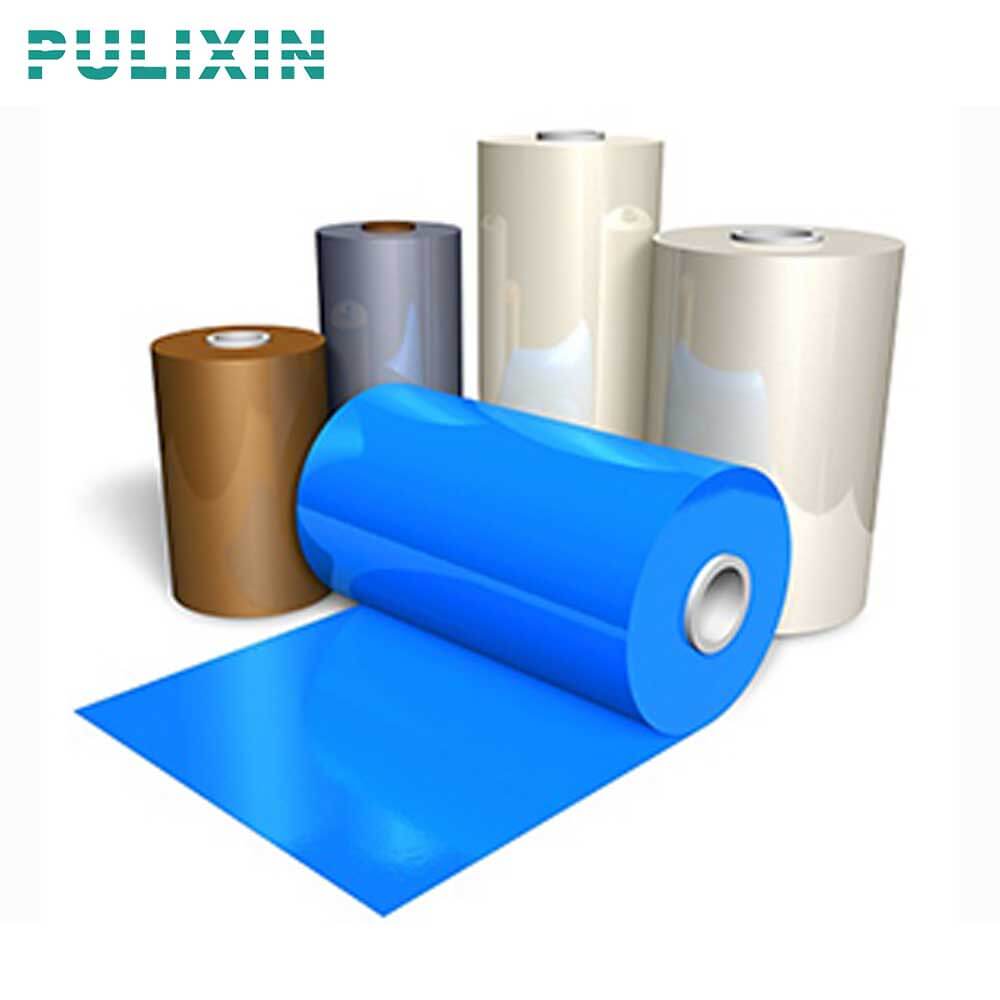

Product name: HIPS plastic rolls

Brand: Pulixin

Origin: Shanghai, China

Width: 300~1400mm

Thickness: 0.2~2.0mm

Weight: 50-150kg/roll

Shape: Roll/Sheet

Color: Natural, Black, White, Color.

Molding Process: Blister packaging

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.