We will contact you within 24 hours about sending free samples

We will contact you within 24 hours about sending free samples

Posted By in Knowledge - PET/PP/PS Sheet manufacturer with 20 years of experience

PET (Polyethylene Terephthalate) sheet is a highly versatile material that finds extensive use in various industries. With its exceptional properties and wide range of applications, PET sheet has become a go-to choice for packaging solutions and beyond. In this article, we will explore the characteristics, benefits, and diverse applications of PET sheets.

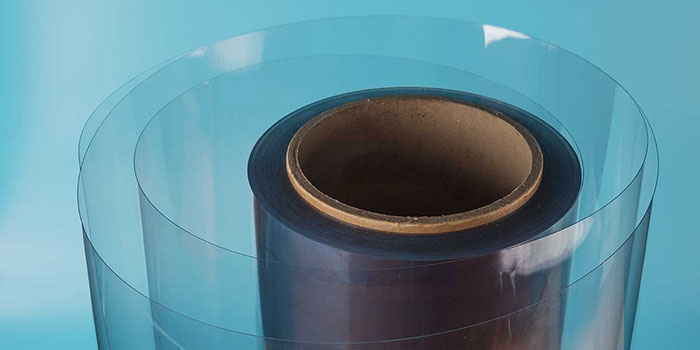

PET sheet is a form of thermoplastic material derived from polyethylene terephthalate resin. It is produced by extruding the resin into a flat sheet form, which can vary in thickness and dimensions depending on specific requirements. PET sheets are transparent, lightweight, and possess excellent dimensional stability, making them suitable for numerous applications.

PET sheets exhibit several key characteristics that contribute to their popularity:

PET sheets are known for their exceptional transparency and clarity, which is similar to glass. This property allows for the display of products or contents with high visual appeal. The transparency of PET sheets enhances the aesthetics of packaging and creates an appealing presentation for consumers.

PET sheets are lightweight, making them easy to handle during transportation, storage, and packaging processes. Despite their lightness, PET sheets are also durable and offer excellent impact resistance. This combination of properties ensures that the packaged products remain protected and secure throughout the supply chain.

PET sheets demonstrate good resistance to various chemicals, including acids and alkalis. This makes them suitable for packaging products that may come into contact with potentially corrosive substances. Additionally, PET sheets are resistant to moisture, ensuring the integrity of the packaged items.

PET sheets can be easily thermoformed into different shapes and sizes, making them adaptable to various packaging requirements. They can be molded, bent, or vacuum-formed to create customized packaging solutions. This formability allows for creative and functional designs, enabling businesses to differentiate their products in the market.

PET sheets offer several benefits that make them an attractive choice for packaging applications:

The high transparency of PET sheets allows for clear visibility of the packaged product, enhancing its market appeal. Consumers can easily see and evaluate the quality, color, and condition of the contents, which can influence purchasing decisions.

PET sheets provide excellent impact resistance, ensuring that the packaged items are protected during handling and transportation. They act as a barrier against physical damage, reducing the risk of breakage or spoilage of delicate products.

PET sheets contribute to lightweight packaging, which has become increasingly important due to environmental concerns and transportation costs. The lightweight nature of PET sheets reduces packaging material usage, optimizes storage space, and minimizes fuel consumption during transportation.

PET sheets are highly recyclable, contributing to sustainable packaging practices. The recycling process for PET sheets involves melting, filtering, and re-extruding the material to produce new sheets or other plastic products. This reduces waste generation and conserves valuable resources.

PET sheets find extensive applications across various industries:

PET sheets are widely used for food and beverage packaging, including bottles, trays, containers, and blister packs. Their transparency allows consumers to see the contents, while their durability ensures product protection and freshness. PET sheets are FDA-approved for direct food contact, making them a safe choice for packaging edible items.

PET sheets are utilized in cosmetic and personal care packaging for items such as shampoo bottles and jars, lotion containers, and cosmetic display trays. The clarity and transparency of PET sheets enhance the visibility of the products, allowing consumers to see the colors and textures of the cosmetics. PET sheets also provide a protective barrier, ensuring the integrity and longevity of the contents.

PET sheets are commonly used in the packaging of electronic and electrical components. They serve as protective covers for items such as mobile phone screens, LCD panels, and circuit boards. The lightweight and impact-resistant nature of PET sheets safeguard delicate electronic components from damage during handling, shipping, and use.

PET sheets find applications in the medical and pharmaceutical industries, where sterile and secure packaging is crucial. They are used for blister packs, pill containers, medical device packaging, and protective covers. The chemical resistance of PET sheets ensures the compatibility of the packaging with various medications and medical devices.

PET sheets are employed in the creation of retail displays, point-of-sale signage, and promotional materials. Their transparency, combined with easy formability, allows for the production of eye-catching displays with vibrant graphics. PET sheets are also weather-resistant, making them suitable for outdoor signage applications.

China has established itself as a leading manufacturer of PET sheets. The country's PET sheet manufacturers adhere to strict quality control measures and employ advanced production technologies. Choosing PET sheets made in China offers several advantages:

China's PET sheet manufacturers benefit from cost-effective manufacturing processes, allowing them to offer competitive pricing without compromising on quality. The country's well-developed supply chain and abundant raw materials contribute to cost efficiencies, making PET sheets from China an economical choice for businesses.

PET sheet manufacturers in China adhere to international quality standards and certifications. They implement strict quality control measures throughout the production process to ensure consistent product quality. This commitment to quality provides businesses with the confidence that they are receiving reliable and high-performing PET sheets.

Chinese PET sheet manufacturers offer a wide range of customization options to meet diverse customer requirements. They can produce PET sheets in various sizes, thicknesses, and colors, allowing businesses to select the most suitable options for their specific applications. Customization capabilities enable tailored packaging solutions and unique product presentations.

Sustainability has become a significant focus in the packaging industry. PET sheet manufacturers in China prioritize eco-friendly practices, such as using recycled materials and implementing energy-efficient production processes. Choosing PET sheets made in China aligns with sustainable packaging initiatives, contributing to environmental responsibility.

PET sheets are versatile materials that offer numerous advantages for packaging and various other applications. Their transparency, lightweight yet durable nature, chemical resistance, and formability make them an ideal choice for industries such as food and beverage, cosmetics, electronics, medical, and signage. PET sheets made in China provide cost-effective manufacturing, high-quality standards, customization options, and sustainable practices.

When considering PET sheets for your packaging needs, exploring the offerings from Chinese manufacturers can be a beneficial option. With their commitment to quality, customization capabilities, and cost efficiencies, PET sheets made in China can contribute to the success of your packaging solutions while meeting your specific requirements.