Nos pondremos en contacto con usted dentro de las 24 horas sobre el envío de muestras gratuitas.

Nos pondremos en contacto con usted dentro de las 24 horas sobre el envío de muestras gratuitas.

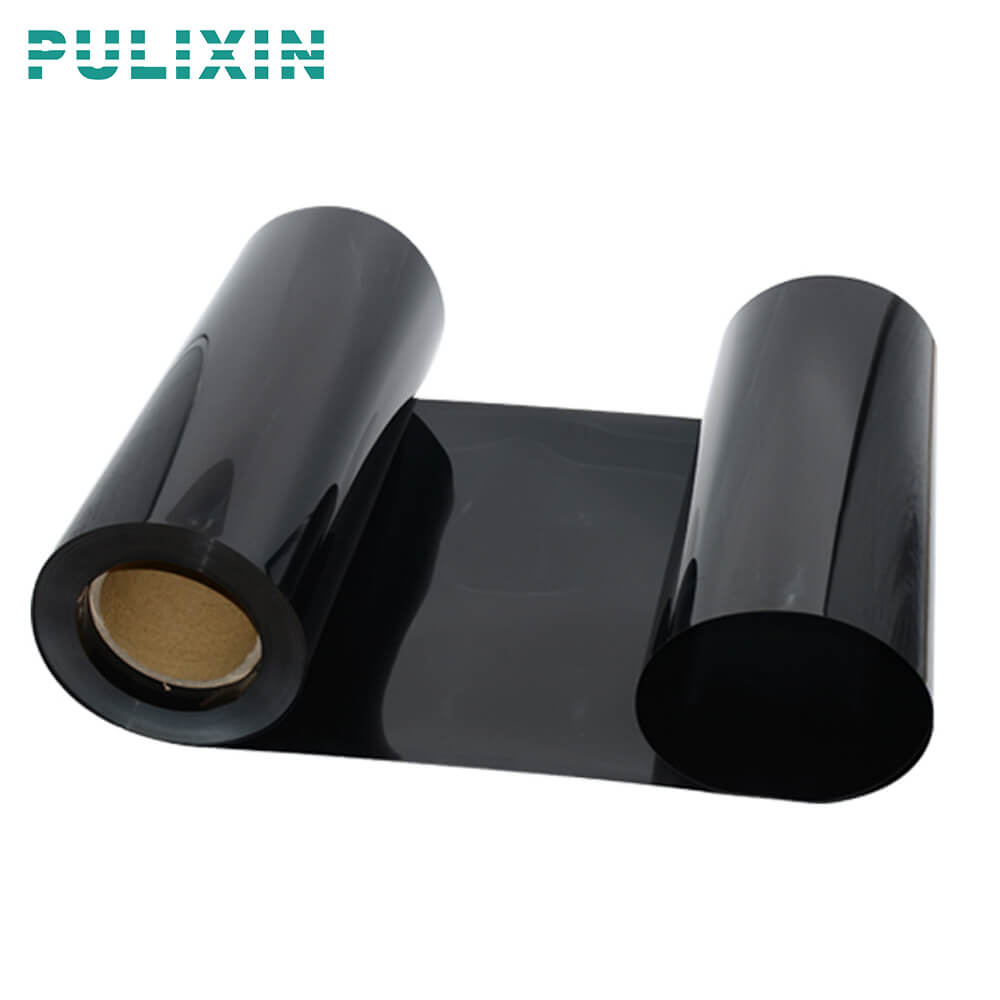

HIPS (High Impact Polystyrene) plastic roll is a type of thermoplastic material that is manufactured in the form of continuous rolls. It is produced by extruding polystyrene resin through a die to form a thin, flexible sheet of plastic. This sheet is then wound onto rolls for storage, transportation, and easy handling in manufacturing processes.

HIPS plastic rolls can be further processed through techniques such as thermoforming, vacuum forming, or printing to create a wide range of products such as packaging trays, disposable cups, signage displays, automotive interior components, and more. The versatility, cost-effectiveness, and ease of processing make HIPS plastic rolls a popular choice for manufacturers looking for durable and economical materials for their applications.

HIPS plastic rolls offer a combination of strength, versatility, cost-effectiveness, and other desirable properties, making them a popular choice for a wide range of industrial and commercial applications.

1. Impact Resistance: As the name suggests, HIPS plastic rolls has high impact resistance, making it suitable for applications where durability and toughness are essential. It can withstand physical shocks without breaking or deforming easily.

2. Versatility: HIPS plastic rolls are versatile and can be easily thermoformed or molded into different shapes and sizes, making them ideal for a wide range of applications across industries such as packaging, signage, automotive, electronics, and more.

3. Cost-Effective: HIPS plastic roll is generally more affordable compared to other plastics like ABS or polycarbonate, making it a cost-effective option for manufacturers and businesses looking to keep production costs low without compromising on quality.

4. Good Printability: HIPS plastic rolls surfaces can be easily printed on using various printing methods such as screen printing, offset printing, or digital printing. This makes it suitable for applications requiring branding, labeling, or decorative purposes.

5. Chemical Resistance: HIPS plastic has good resistance to chemicals, making it suitable for applications where exposure to various chemicals or solvents is expected, such as in the packaging of certain products or in laboratory equipment.

6. Lightweight: HIPS plastic rolls is relatively lightweight, which can be advantageous in applications where weight is a concern, such as in automotive components or lightweight packaging.

7. Recyclability: HIPS plastic roll is recyclable, contributing to sustainability efforts and reducing environmental impact. It can be recycled into new HIPS products or other plastic products, reducing the need for virgin plastic production.

8. FDA Approval: HIPS plastic roll is approved by the FDA for certain food contact applications, making it suitable for use in food packaging and containers.

1. Product packaging: Due to its low weight, resistance to moisture, and simplicity in molding into various forms and sizes, HIPS plastic roll is frequently utilized in packaging applications. The packaging of consumer items including toys, electronics, and cosmetics frequently uses this method.

2. Toys: HIPS plastic roll is used in the manufacture of toys and other children’s products due to its lightweight, impact resistance, and ability to be easily molded into different shapes and colors.

3. Electrical and electronic equipment: HIPS plastic roll is frequently used as a casing for electrical and electronic equipment because of its exceptional dimensional stability and resistance to moisture.

4. Medical devices: Due to its high impact resistance, low weight, and simplicity of processing, HIPS plastic roll is utilized in the manufacture of a variety of medical equipment, including orthopedic splints.

5. Food packaging: Because HIPS plastic roll is easily moldable into a variety of forms and sizes and has strong moisture resistance, it is used to make food packaging such as clamshell containers.

Components:

HIPS conductive plastic rolls are made by blending HIPS resin with carbon black, which is a highly conductive material. The combination of these two materials results in a plastic compound that has excellent electrical conductivity.

Características:

Provide all the functions of a single material. This eliminates the need for additional materials, such as conductive coatings or conductive inks, which can reduce production costs and increase production efficiency.

HIPS conductive plastic rolls can be tailor-made to meet the specific requirements of end-products.

Improve product’s mechanical properties, color stability, and dimensional stability.

Aplicaciones:

The applications of HIPS conductive plastic rolls are diverse, ranging from mobile chargers, power sockets, and earphones, to electronic components and pallets, which require good electrical conductivity and improved mechanical properties.

Components:

High Impact Polystyrene (HIPS) Material: This is the main component of this product. HIPS is an impact-resistant, rigid plastic commonly used to make packaging materials, electronic device casings and other products that require strength and durability.

Coatings: This type of roll may have a special coating applied to the surface of the HIPS substrate to give it additional properties or add specific functionality. The nature of the coating may vary depending on the application; for example, an antistatic coating may be selected to prevent the build-up of static electricity, or a coating may be selected with special anti-corrosion properties.

Other Additives: Depending on specific product requirements, other ingredients may be added to improve product performance. For example, fillers may be added to increase the strength of the product or improve its flame retardant properties.

HIPS Coating Plastic Rolls may be formulated and composed differently in different applications to meet specific requirements and standards. These rolls are commonly used in packaging, construction, advertising, electronics, and more.

Características:

Impact resistance: The HIPS coating plastic rolls has high impact strength, allowing the roll to withstand a certain degree of impact and pressure during transportation and handling.

Surface coating: HIPS coating plastic rolls usually has a special surface coating, which can provide different properties according to needs, such as anti-static, anti-corrosion, waterproof, etc.

Electrical Properties: Some HIPS coating plastic rolls may have electrically conductive properties that effectively discharge static electricity in static-sensitive environments, thereby protecting electronic equipment and components from damage.

Customizability: HIPS coating plastic rolls stock can often be customized to customer requirements, including different thicknesses, widths, colors, coating options, etc.

Environmentally friendly: HIPS coating plastic rolls is a recyclable plastic material, so this roll is environmentally friendly to a certain extent.

Aplicaciones:

HIPS Coating Plastic Rolls are commonly used in various types of packaging, including food packaging, electronic product packaging, cosmetic packaging, etc. Its impact resistance and customisation make it ideal for packaging.

| Item | High Impact Polystyrene Sheet Roll, HIPS Plastic Roll, Rgid HIPS Film |

| Marca | PULIXIN |

| Origen | Shanghai, China |

| Ancho | 300~850mm |

| Espesor | 0,2~2,0 mm |

| Peso | 50-150kg/roll |

| Forma | Rollo/Hoja |

| Material | 100% virgen |

| Color | Black, White, Color, Natural, Transparent, Translucent. |

| Actuación | Conductive, Antistatic, EOVH High barrier |

| Surface treatment | Matte, high gloss, flocking, etc. |

Si es posible, sugiera amablemente su industria/proceso de trabajo, presión de trabajo, medio de trabajo, etc. Una solicitud detallada ayuda a obtener una solución personalizada mejor adaptada. Gracias por su paciencia.

su solicitud será respondida dentro de las 3 horas, por favor, preste atención a su correo electrónico.